Фільтри для пилу є, по суті, першою лінією захисту від різноманітних повітряних частинок на фабриках, деревообробних та хімічних підприємствах. Ці фільтрувальні системи можуть затримувати дрібні частинки пилу розміром до PM2.5 та PM10, зменшуючи рівень пилу в повітрі майже на 95% згідно з дослідженням, опублікованим торік в BMJ Thorax. Реальна вигода? Працівники не вдихають шкідливі речовини, що викликають серйозні захворювання легень. Такі стани, як силикоз та професійна астма, вражають приблизно 2 мільйони людей, зайнятих у різних галузях в Америці, щорічно. Краще фільтрування означає загалом здоровіше робоче середовище.

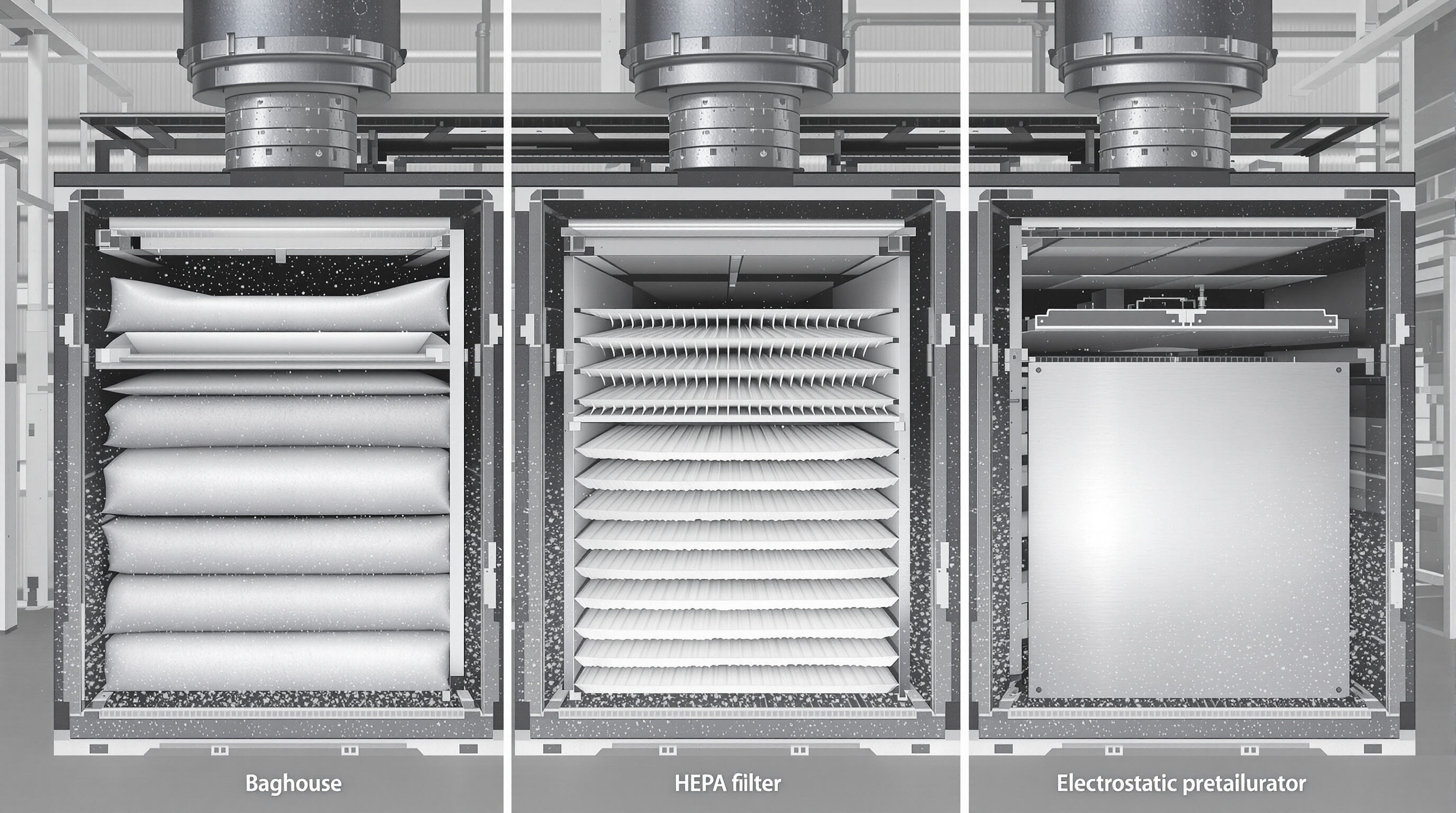

Правильний вибір високоефективних фільтрів дозволяє затримувати неприємні частинки пилу, які літають під час шліфування, різання матеріалів або просто переміщення речей у промислових умовах. Наприклад, рукавні фільтри дуже добре справляються з утриманням великих частинок пилу на цементних заводах, досягаючи майже ідеальних показників ефективності. Тим часом електрофільтри чудово справляються з дрібним пилом, що утворюється в литтях. За даними досліджень, проведених минулого року, на робочих місцях, де встановлені якісні системи фільтрації пилу, зафіксовано приблизно на 30% менше випадків захворювань дихальних шляхів серед працівників порівняно з тими, хто не використовує належним чином фільтрацію. Цілком логічно, правда?

| Промисловість | Основний ризик для здоров'я | Користь фільтрації |

|---|---|---|

| Дереворобництво | Астма, викликана деревним пилом | зниження впливу PM10 на 80% |

| Металообробка | Металеве пилове лихоманкове стан | на 50% нижчий рівень дихальних частинок |

| Фармацевтичні продукти | Хімічне забруднення | очищення повітря класу HEPA 99,97% |

Промислові фільтри для пилу роблять більше, ніж захищають здоров'я працівників, вони також допомагають підприємствам дотримуватися складних вимог OSHA PEL та відповідати рекомендаціям EPA щодо якості повітря. Багато провідних виробників останнім часом почали додавати ці датчики PM у реальному часі в свої системи. Ці датчики фактично виступають у ролі розумних контролерів, які регулюють потужність роботи фільтрів залежно від стану повітря. Деякі підприємства повідомляють, що їм вдалося скоротити витрати на енергію на 20–25% після модернізації. Для керівників виробництва це поєднання захисту здоров'я працівників і економії на комунальних послугах зробило сучасні системи фільтрації пилу майже обов'язковими сьогодні, особливо в умовах посилення прагнення компаній до екологічно чистих виробничих процесів.

Мішкові фільтри дуже добре справляються з усією пилом, що утворюється під час виробництва цементу, у металообробних цехах та при деревообробці, де частинки літають скрізь. Система працює шляхом просмоктування повітря крізь тканинні мішки, які затримують дрібні частинки розміром до приблизно 5 мікронів. За нормальних умов ці фільтри можуть затримати майже все, що проходить крізь них, досягаючи іноді ефективності приблизно 99,9%. У нових моделях передбачено автоматичні функції очищення, наприклад, імпульсні системи, які видаляють накопичений пил без зупинки всієї операції. Це означає, що підприємства економлять час на обслуговування, тому що їм не потрібно зупиняти все обладнання для очищення так часто. Порівняно зі старими ручними методами, підприємства повідомляють про скорочення часу простою від 30% до майже половини, залежно від того, наскільки серйозною є проблема з пилом.

Фільтри HEPA, що означають High Efficiency Particulate Air, затримують приблизно 99,97% частинок, які мають розмір 0,3 мікрона або менше. Ще більш просунуті фільтри ULPA йдуть далі, затримуючи до 99,999% частинок завбільшки до 0,12 мікрона. Галузі, такі як виробництво ліків і виготовлення напівпровідників, значною мірою покладаються на ці системи фільтрації, адже чисте повітря означає кращу якість продукції. Виробники також вносять поліпшення, додаючи, наприклад, антимікробні покриття та шари активованого вугілля. Ці додатки допомагають боротися як з шкідливими ЛОС, так і з різноманітними патогенами одночасно, забезпечуючи додатковий захист від забруднювачів.

Електростатичні фільтри працюють за рахунок надання частинкам пилу електричного заряду, а потім притягують їх до збірних пластин, які мають протилежний заряд. Вся система здатна затримувати від 90 до 99 відсотків цих мікрочастинок, які ми бачимо у зварювальних димах або залишках котлів. Проте нещодавно трапилася цікава подія з новими фільтрами, вкритими нановолокнами. Вони створюють набагато щільніші мережі волокон, що означає, що вони затримують навіть менші частинки на субмікронному рівні, не ускладнюючи при цьому прохід повітря. Що це означає? Наразі підприємства, які використовують цю нову технологію, насправді економлять близько 15 до, можливо, 20 відсотків на енергобілі, порівняно зі старими електростатичними системами. Така економія має велике значення, коли компанії прагнуть скоротити витрати, одночасно виконуючи екологічні стандарти.

Промислові фільтри для пилу сьогодні оснащені різноманітними спеціалізованими пилозбирачами, призначеними для вирішення різних проблем з якістю повітря на фабриках і заводах. Системи пилозбирання типу Baghouse повсюдно використовуються в важких галузях промисловості, оскільки вони можуть затримувати до 99,9% частинок розміром менше 10 мікронів. Циклонні пилозбирачі також добре справляються з більшими частинками, використовуючи відцентрові сили для відокремлення більших шматочків брухту. Деякі підприємства почали поєднувати електростатичні технології з традиційними тканинними мішками, створюючи гібридні системи, які щорічно економлять приблизно 1,2 млн доларів на витратах на технічне обслуговування, згідно з останніми звітами металообробних майстерень. Ці продвинуті системи фільтрації допомагають не тільки дотримуватися вимог OSHA та EPA, а й забезпечують безперервність роботи підприємств завдяки модульній конструкції та автоматичним функціям очищення, які зменшують кількість непередбачених зупинок.

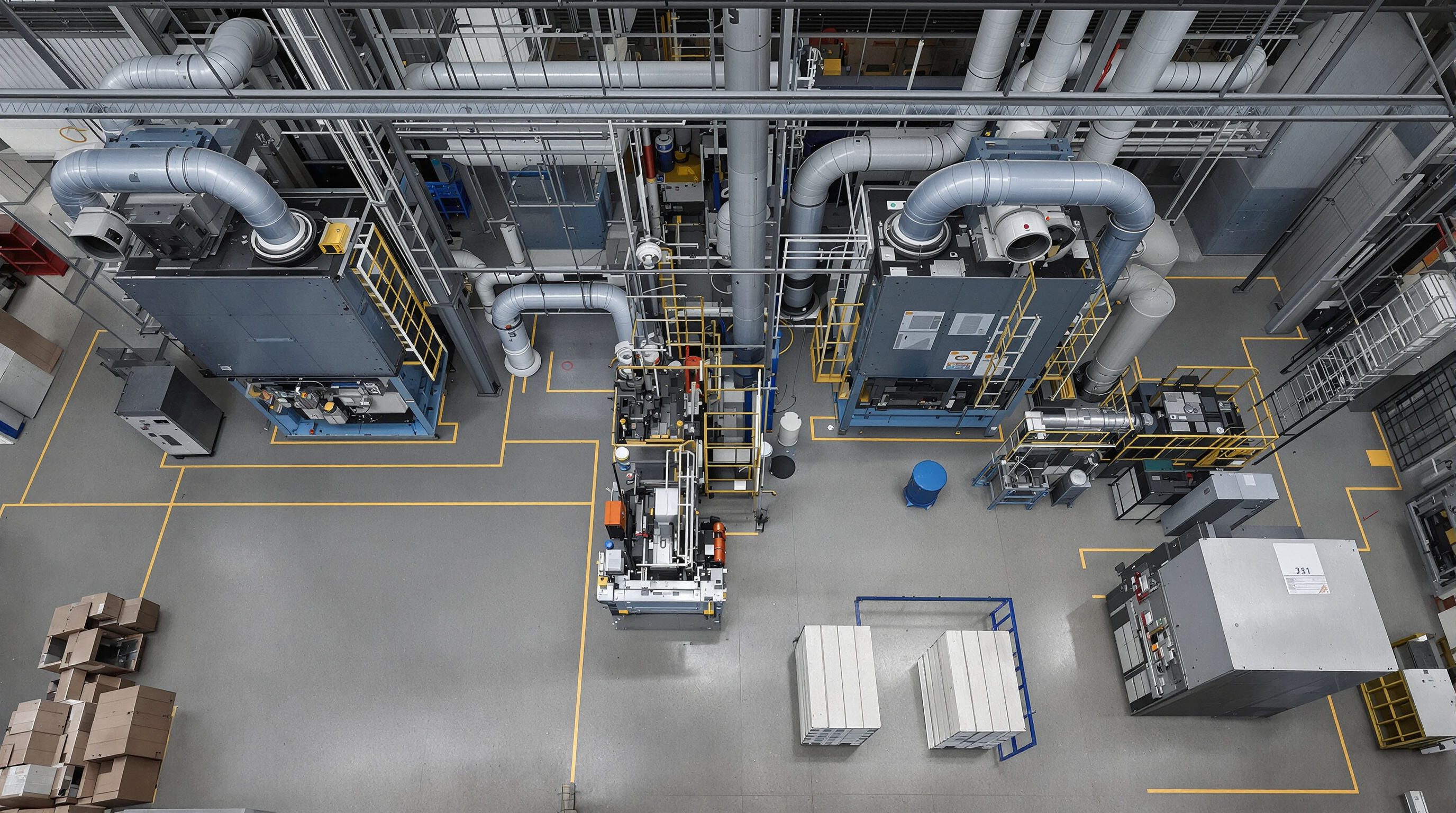

Стратегічне розміщення на відстані 15–20 футів від обладнання, що виробляє пил, підвищує ефективність його збору на 40–60% згідно з дослідженнями моделювання повітряних потоків. Ведучі постачальники рекомендують поєднувати верхні витяжні шафи з припідлоговими точками відбору повітря під час зварювальних або шліфувальних робіт для протидії підйомним пиловим частинкам. Проектувальники систем визначають три пріоритетні фактори:

Налагоджена промислова пил фільтрувальна система зменшує повітряні забруднювачі на 87–92%, споживаючи на 25% менше енергії порівняно з традиційними системами.

Пилові фільтри в промислових умовах запобігають накопиченню шкідливих частинок до небезпечних рівнів, особливо важливо в замкнених просторах, таких як виробничі ділянки, де працівники проводять багато годин. Фільтри HEPA разом із електростатичними системами особливо добре затримують дрібні частинки розміром менше 2,5 мікрона, які ми називаємо PM2.5. Для досягнення найкращих результатів компаніям потрібно встановлювати витяжні вентиляційні отвори якомога ближче до місць, де пил насправді утворюється. Розташування вентиляції безпосередньо біля джерела суттєво впливає на підтримання чистоти в різних частинах приміщення. Також важливо забезпечити щільні ущільнення навколо корпусів фільтрів, адже навіть маленькі зазори можуть дозволити пилу потрапити назад у повітря. Деякі сучасні системи тепер використовують нановолоконні технології, які значно підвищують їхню здатність затримувати речовини, такі як кристалічна окись кремнію, яка становить серйозну загрозу для здоров'я при вдиханні. Регулярне очищення та заміна дозволяють цим системам працювати з ефективністю понад 95% більшу частину часу. Усі ці рівні захисту допомагають зберігати здоров'я працівників на фабриках, де просто немає місця для традиційних рішень у плані вентиляції.

Постійний контроль якості повітря в приміщеннях залежить від мережі датчиків, які вимірюють такі параметри, як наявність частинок у повітрі, рівень вологості, концентрацію діоксиду вуглецю та ті самі неприємні легкозаймисті органічні сполуки, які ми називаємо ЛОС. Якщо дані в реальному часі вказують на відхилення, менеджери об'єктів можуть втрутитися та усунути проблеми, перш ніж вони перетворяться на серйозні питання. Дослідження показують, що будівлі, які дотримуються стандарту ASHRAE 62.1, як правило, мають кращі показники здоров'я мешканців. Слідкування за показниками якості повітря корисне не лише для людей — це також зменшує ризики юридичних проблем для власників будівель. Регулярна калібрування датчиків забезпечує їхню точність, коли приходять аудитори. Заміна фільтрів відбувається відповідно до суворих термінів, встановлених екологічним законодавством. Програмне забезпечення, що об'єднує всі системи, створює детальні звіти про відповідність вимогам, які справді корисні під час перевірок регулюючими органами. Ці звіти розповідають історію про ефективність роботи об'єкта. Розумні системи автоматично надсилають попередження, коли стандарти починають порушуватися. Спеціальні резервні режими активуються при раптовому зростанні рівня забруднювачів. А регулярне обслуговування забезпечує належну роботу фільтрів, запобігаючи їхньому зношенню, що часто трапляється в старших будівлях.

Сучасні промислові фільтри для пилу тепер використовують досить ефективні інженерні рішення, щоб зменшити споживання енергії. Приводи змінної частоти автоматично регулюють швидкість роботи вентиляторів залежно від кількості пилу, який перебуває в повітрі в даний момент. Це означає, що підприємства можуть економити від 15 % до 40 % на електроенергії, коли рівень забруднення знижується. Ще одне суттєве покращення — це нові фільтрувальні картриджі, які мають спеціальні шари нановолокна всередині. Вони продовжують затримувати ті самі частинки, але створюють набагато менший опір потоку повітря порівняно зі старими моделями — приблизно на 30 % менше опору. І це ще не все — модульні конструкції дозволяють підприємствам ввімкнення фільтрів лише в тих місцях, де працівникам вони потрібні зараз, замість постійної роботи всіх систем у порожніх приміщеннях. Усі ці зміни мають значення, адже витрати на енергію часто складають більше половини від загальних витрат підприємств на експлуатацію систем фільтрації протягом часу. Підприємства, які модернізували обладнання за допомогою цих більш інтелектуальних систем керування та енергоефективних матеріалів, побачили, що їхні рахунки за електроенергію знизилися в середньому на 25–35 %.

Сьогодні промислові фільтри для пилу виходять за межі простої відповідності вимогам щодо охорони навколишнього середовища. Нові мембрани, виготовлені з таких матеріалів, як полімери рослинного походження та перероблений поліестер, насправді розпадаються приблизно на 70% швидше порівняно з традиційними синтетичними матеріалами. Фільтри також служать довше завдяки системам самоочищення з імпульсними соплами, що означає, що ми викидаємо на 40% менше відходів щороку. Деякі компанії використовують системи замкненого циклу, які дозволяють відновлювати близько 90% матеріалів зі старих деталей замість відправлення їх на звалища. Нещодавній огляд ринку промислового обладнання в Північній Америці показав, як ці екологічні поліпшення реально допомагають досягати цілей ESG. Підприємства вже не просто скорочують викиди вуглецю, вони також підтримують чистоту повітря навколо своїх об'єктів, щоб мешканці навколишніх районів могли краще дихати.

Промислові фільтри для пилу — це системи фільтрації, призначені для уловлювання завислих частинок, що зменшують рівень пилу на виробничих майданчиках. Вони покращують якість повітря, захищають здоров'я працівників та допомагають підприємствам дотримуватися вимог OSHA та EPA. Крім того, вони сприяють енергозбереженню та здійсненню більш екологічних виробничих процесів.

Фільтри типу рукавних уловлюють великі частинки пилу на цементних заводах, тим часом як електростатичні фільтри впораються із дрібним пилом з оксиду кремнію у литтєвих цехах. Фільтри HEPA та ULPA забезпечують високоефективне очищення повітря, уловлюючи до 99,999% мікрочастинок, що є корисним для галузей, таких як фармацевтика та виробництво напівпровідників.

Стратегічне розміщення пиловловлювачів біля обладнання, що виділяє пил, максимізує ефективність його збирання. Важливими аспектами проектування системи є швидкість повітряного потоку, вибір фільтруючого матеріалу та рекуперація енергії за допомогою регенеративних технологій, що має ключове значення для ефективного зменшення забруднення повітря.

Гарячі новини

Гарячі новини2025-01-17

2025-01-13

2025-01-08

2024-12-27

2024-12-23

2024-12-16