מסננים אוויר במערכות ה-Ventilation הם די אפקטיביים בפינוי דברים מהאוויר שאנחנו נושמים. הם תופסים בערך 90% מהملوثים הנפוצים כמו אבק, אבקת אבקנים, ו-VOCs הרעים לפני שהם דוחפים את האוויר הנקי חזרה לחדרים שלנו. לפי סטנדרטים של ASHRAE משנת 2023, מסננים מודרניים יכולים לתפוס חלקיקים עד גודל של מיקרון אחד, מה שאומר שהם עוצרים הרבה מהדברים שמקשים על הנשימה לאנשים עם אלרגיות או בעיות נשימה. עיצובים חדשים של מסננים קורגים פועלים אפילו טוב יותר בגלל שטח פנים גדול יותר. המרחב הנוסף הזה מאפשר להם לאגור יותר אבק ופסולת בעוד האוויר יכול לזרום דרכם בצורה סבירה, כך שהمبנים נשארים נעימים ללא מאמץ מוגזם של המערכת.

סולם ה-MERV (Minimum Efficiency Reporting Value) (1-16) מודד את יעילות המסנן בתפיסת חלקיקים באוויר:

| MERV דירוג | יעילות תפיסת חלקיקים | ת Peblications טיפוסיות |

|---|---|---|

| 8-10 | 70% מהחלקיקים בגודל 3-10 מיקרון | בניינים מגורים |

| 13-16 | 85-95% מהחלקיקים בגודל 0.3-1 מיקרון | בתי חולים, מעבדות |

בסביבות מסחריות, מסננים עם דרגת MERV 13+ מפחיתים חלקיקים שמעוררים אלרגיות ב-60% בהשוואה למסננים בסיסיים עם דרגת MERV 6 (מועצת איכות אויר 2023), ומשפרים משמעותית את איכות האויר הפנימי.

מסננים מתקדמים להחלפה משיגים ייחוס של 95% בפיחوم PM1 (חומר חלקיקי •1 מיקרון) באמצעות תווך אלקטרוסטטי ושכבת צפיפות מדורגת. בדיקות על ידי צד שלישי לפי סטנדרט ASHRAE 52.2 מאמתות שמסננים יעילים שומרים על יעילות של •¥99% גם לאחר שש месяцев של פעולה במערכות HVAC מסחריות טיפוסיות.

מתקנים המשתמשים בפלטרים מסוג MERV 14 מדווחים על 28% פחות תלונות נשימתיות מצד המתאכסנים (מחקר BOMA 2023 באיכות האוויר הפנימי). עקרונות פעולה מומלצים כוללים החלפת פילטרים מדי שלושה חודשים ופיקוח בזמן אמת על זרימת האוויר כדי לאזן בין יעילות הסינון לצורכי הניקוז. בתי ספר שאמצו מערכות סינון תואמות לתקן ISO 16890 צפינו ירידה של 19% בשיעור ההיעדרויות של תלמידים שמקושרות לאיכות האוויר.

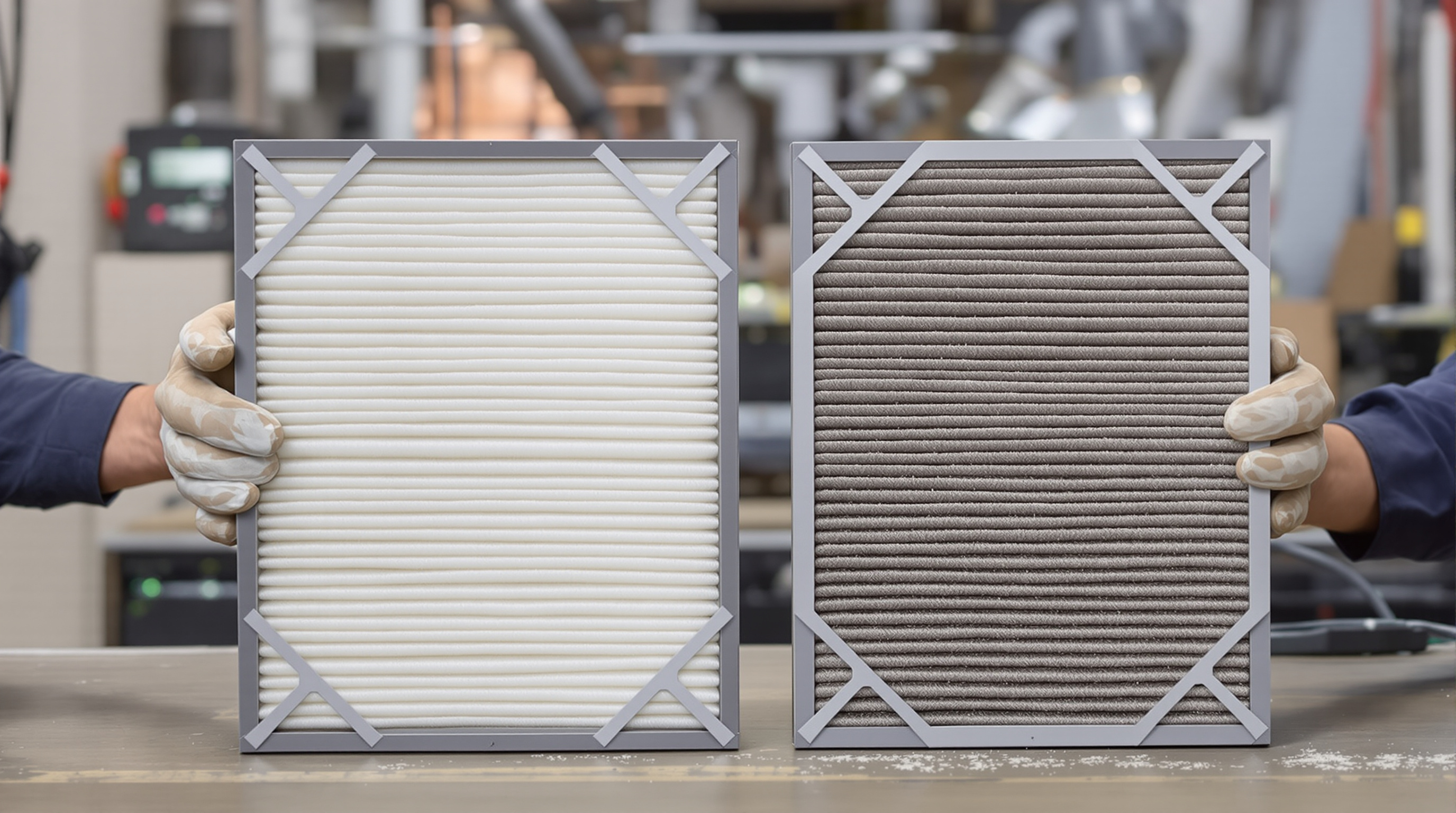

ה קרטידג' סינון אוויר המשחקת תפקיד גדול ביעילות מערכת ה- HVAC שכן היא קובעת כמה התנגדות יש לזרימת האוויר. כשהמסננים האלה נקיים, האוויר זורם בחופשיות במערכת, מה שפירושו שהמנוע של המדחס לא צריך לעבוד קשה וכמות השימוש האנרגטי הכוללת יורדת. חישבו על זה כך: כשכל המערכת פועלת חלק, ה- HVAC זקוק רק לשבריר ממה שהוא Normally היה צריך כדי לשמור על טמפרטורות נעימות במרחבים, במיוחד ביום הקיץ החם או הלילות הקשות של החורף, כשאנחנו באמת סומכים על האיתר ומערכת הקירור.מצד שני, מסננים מלוכלכים יוצרים כל מיני בעיות. המערכת מסתיימת את ההפעלה למשך זמן ארוך מדי מכיוון שהיא לא יכולה לדחוף מספיק אוויר, וזה למעשה גורם להBILL האנרגיה לעלות בכ- 15 אחוז, על פי דוחות תעשייתיים שונים שנראו לאורך השנים.

קרטיסים סתומים בפילטרי אוויר מעלים את הלחץ הסטטי, מה שגורם למרכיבי מיזוג האוויר לעבוד קשה מדי. זה מוביל לزيادة בצריכת האנרגיה של הפקקים וצמצום ביעילות שחלוף החום. הקומפרסורים פועלים זמן רב יותר כדי לעמוד בדרישות התרמוסטט, מה שמעלה את הנזק המכאנלי וצריכת הקילוואט לשעה. האפקט המצטבר מקצר את חיי המחשבה ומעלה את עלות התפעול.

מה קורה כאשר תנועת האוויר נחסמת? כל המערכת מתחילה לפעול אחרת. מסננים שמילאו בערך 80% מקיבולתם מקטינים את זרימת האוויר ב-20% בערך. כתוצאה מכך, המנחות נאלצות לעבוד קשה יותר כדי לשמור על תקשורת מספקת. יש גם משהו שנקרא חוקי ההזדהות של המנחות שמושפעים מהסיטואציה הזו. בעיקרון, ככל שהלחץ עולה, האנרגיה הנדרשת לא רק שגדלה באופן יחסי - אלא גדלה באופן משמעותי יותר ממה שניתן לצפות. התבוננו במה שקורה כאשר זרימת האוויר ירדה ב-50%. לפתע פתאום, המנחות נזקקות לשלוש פעמים יותר כוח כדי לבצע את העבודה שלהן. קפיצה כזו בצריכת האנרגיה יוצרת בעיות משמעותיות מבחינת יעילות ותפעול.

ตลับกรองอากาศขั้นสูงด้วยสื่อที่ออกแบบมาเป็นพิเศษช่วยลดแรงดันสถิตย์ ขณะที่ยังคงประสิทธิภาพการจับอนุภาคสูง ตัวกรองเหล่านี้ให้ประสิทธิภาพ MERV 13-16 พร้อมความต้านทานเริ่มต้นต่ำกว่า 0.5 นิ้ว w.g. ซึ่งต่ำกว่าตัวกรองมาตรฐาน 20-30% การลดแรงต้านช่วยให้การไหลของอากาศสม่ำเสมอ ทำให้สถานที่ติดตั้งสามารถประหยัดพลังงานระบบ HVAC ได้ 8-12%

للحصول على ترشيح جيد، يجب إيجاد التوازن المثالي بين احتجاز الجسيمات ونوعية ما يمكن للنظام تحمله فعليًا. تعمل مرشحات MERV ذات الدرجات الأعلى من 13 بشكل ممتاز في احتجاز الجسيمات الدقيقة التي تقل عن الميكرون، ولكن علينا أن نكون واقعيين، فكثير من أنظمة التدفئة وتكييف الهواء القديمة لا تستطيع دفع كمية كافية من الهواء عبر هذه المرشحات. قبل إجراء أي تحسينات، يجب على المهندسين التحقق أولًا من قيم الضغط الثابت. قد يكون من الجدير النظر في وسائط الفلاتر الطيّة، إذ توفر هذه التصاميم ما يقارب 150٪ إضافية من مساحة السطح مع الحفاظ على انخفاض المقاومة مقارنة بالخيارات القياسية. منهجية أخرى هي تركيب مراحل متعددة من الترشيح في جميع أرجاء النظام. لقد شهدنا نجاح هذا الحل في المنشآت التي تكون فيها الحفاظ على تدفق الهواء أمرًا بالغ الأهمية، مع الاستمرار في جعل التحكم بالجسيمات من الأولويات الأساسية.

ตลับตัวกรองอากาศที่ปรับปรุงแล้วช่วยลดต้นทุนด้วยการเพิ่มประสิทธิภาพพลังงานและลดแรงกระทำทางกล ตัวกรองประสิทธิภาพสูงสามารถจับสิ่งปนเปื้อนได้มากขึ้น ทำให้อายุการใช้งานระหว่างการบำรุงรักษายาวขึ้น 30-50% และลดค่าใช้จ่ายแรงงานและวัสดุ อีกทั้งยังช่วยลดความเครียดของระบบ ซึ่งช่วยลดความเสี่ยงของความเสียหายที่อาจเกิดขึ้น โดยแต่ละครั้งอาจสูงกว่า 5,000 ดอลลาร์ในกิจการพาณิชย์

שמירה על ניקיון ותפעול תקין של פילטרים להחלפת אוויר במערכות קירור וחימום (HVAC) היא קריטית לייעילות המערכת. כאשר הפילטרים נקיים, הם יוצרים כרבע מההתנגדות לזרימת האוויר בהשוואה לפילטרים מלוכלכים, מה שאומר שהקומפרסורים והמנועים לא צריכים לעבוד קשה באותה מידה. מנהלי מבנים רבים מציינים חיסכון של כ-10 עד 15 אחוזים על עלויות האנרגיה החודשיות שלהם, לאחר שהחלו לעקוב אחרי תכניות תחזוקה קבועות. התוצאות הטובות ביותר מתקבלות כאשר משתמשים בפילטרים איכותיים עם דירוג MERV 13 עד 16, ומשנים אותם בהתאם לשימוש בפועל ולא במרווחי זמן קבועים. גישה זו לא רק חוסכת כסף, אלא גם מאריכה את חיי השימוש של הציוד במבנים מסחריים.

מחקר שנמשך שנה של שלושה בנייני משרדים מהדרגה A חשף תוצאות נמדדות כתוצאה מהחלפת מערכות הפילטרים למערכות פילטרים בעלי קיבולת גבוהה:

| מטרי | לפני השדרוג | לאחר השדרוג | השפרה |

|---|---|---|---|

| ממוצע עלות אנרגיה | 28,500$ לחודש | 24,100$ לחודש | -15.4% |

| חליפת מסננים | 6/שנה | 3/לשנה | -50% |

| שיחות שירות להזנת מיזוג | 17/לשנה | 9/לשנה | -47% |

החיסכון המשולב הביא לתקופה של 7 חודשים להחזרת ההשקעה, ללא התחשבות בהפצה מחיוך רכושנים ממושך ובריאות תושבים טובה יותר

שדרוג למסננים יעילים מחייב הערכה זהירה של מגבלות מערכת מיזוג. למרות שהמסננים משפרים את איכות האוויר, הם חייבים להתאים את עוצמת זרימה, לחץ סטטי ומנועי מאייד כדי למנוע בעיות בפעילות

לא כל מערכות מיזוג תומכות במסננים מסוג MERV 13+ ללא שינוי. מערכות שתוכננו למסננים MERV 8-11 עלולות לחוות הפחתת זרימת אויר ב-12-25% בשעת שדרוג, מגדיל את צריכה האנרגטית של המנורת עד 15% (ASHRAE 2024). הערכה לפני השדרוג צריכה לאמת:

שדרוגים מודרניים מדגישים עיצובי לחץ נמוך כדי לאפשר סינון יעיל. השוואות מרכזיות כוללות:

| מפרט | מסננים סטנדרטיים | מסננים יעילים |

|---|---|---|

| לחץ נפילה ממוצע | 0.25-0.35 אינץ' H2O | 0.4-0.6 אינץ' H2O |

| קיבולת זרימת אוויר | 1,200-1,500 CFM | 800-1,000 CFM |

| גודל תעלה מומלץ | 10"-14" | 14"-18" |

בחרו פילטרים קורות עם שטח פנים גדול ב-40-60% כדי לשמור על זרימת אוויר תוך כדי שמירה על תחזית גבוהה של ניצול חלקיקים.

מערכות מיזוג מצוידות בсенסורים של אינטרנט של הדברים (IoT) שיכולות לשנות את מהירות המנוף בהתאם לירידות הלחץ בزמנן. התאמות חכמות אלו מפחיתות את בזבוז האנרגיה ב-18 עד 22 אחוזים בהשוואה לדגמים ישנים עם מהירות קבועה, במיוחד כאשר מותקנים פילטרים עם דירוג MERV גבוה. בנוסף, במערכות יש תוכנה מתקדמת שקובעת מתי יש להחליף פילטרים. האלגוריתמים מזהים את כמות האבק שנאגרת לאורך הזמן, את סוג העונה החולפת, ואת תיעוד התפעול הקודם. הדבר הזה מותאם את כוח הסינון בפועל ליכולת המערכת, מה שמונע עליה חלקים ומחסוך כסף לאורך זמן.

תנאי הסביבה משפיעים משמעותית על חיי הסוללת של פילטר האויר. בסביבות עם ריכוז גבוה של חלקיקים, כמו מפעלים, הפילטרים נטענים ב-30%-40% מהר יותר מאשר בסביבות משרד סטנדרטיות. מעקב אחר ריכוז האבק עוזר למנוע רוויה מוקדמת ומשמר את עקביות הביצועים של הפילטר.

| סוג הסביבה | אורך חיים ממוצע | השפעה על יכולת האבק |

|---|---|---|

| משרד סטנדרטי | 6-9 חודשים | קו בסיס |

| לחות גבוהה | 4-6 חודשים | ירידה של 25% בכמות |

| תעשייתי | 2-4 חודשים | האטה של 50% בעומס |

החלפת פלטרים בהתאם להנחיות היצרן: אחת ל-90 ימים ברוב סביבות מסחריות, או אחת ל-45–60 ימים בסביבות פעילות גבוהות. השהיות בהחלפות עלולות להגביר את התנגדות הזרימה עד 150%, מה שגורם למפעnels לצרוך 15–20% יותר אנרגיה (כתבת ניהול תשתיות). לוחות זמנים המבוססים על השימוש מצליחים יותר במתכונת קבועה שכן הם מזיזים את התפעול בהתאם לצורך בפועל של המערכת.

ביצוע בדיקות מראה חודשיות לפגיעות וביצוע ניקוי בפולס של אויר דחוס במהלך הפעלה כאשר זה רלוונטי. טיפול תקין מאריך את חיי הפלטר ב-30% ומספק רכיבים צמודים למטה כמו סלילים ומדחסים. תשתיות עם פרוטוקולים כתובים לתפעול חווית 22% פחות תיקונים דחופים במערכות מיזוג אויר בהשוואה לאלה המשתמשות בגישה ריאקטיבית.

מערכות מיזוג מתקדמות מצוידות כיום בсенסורים לחץ דיפרנציאלי שמעקבים בזמן אמת עד כמה מסתבכים המסננים. כאשר ההתנגדות עולה על הרגיל, הסנסורים שולחים התראות כדי להודיע לצוותי תחזוקה שמשהו דורש תשומת לב. מחקרים מצביעים על כך שמערכת כזו יכולה להפחית את תקלות הפתע בכ-40%, מה שמהווה נושא משמעותי bagiילי מתקנים. בנוסף, היא תורמת לחיסכון באנרגיה, שכן מסננים אינם מוחלפים מוקדם מדי או מאוחר מדי. הנתונים שנצברים מוזנים למעשה לתוך מודלים חכמים לתחזיות. מודלים כאלה עוזרים לחברות להימנע מהוצאות על החלפות לא הכרחיות של מסננים ועל תיקונים דחופים, וכך trimming הוצאות תפעוליות ב-18% לאורך זמן, לפי דוחות מתחום התעשייה.

ตลับกรองอากาศมีความสำคัญในระบบ HVAC เนื่องจากช่วยดักจับมลพิษในอากาศ เช่น ฝุ่น ละอองเกสร และ VOCs ทำให้อากาศสะอาดขึ้นและช่วยรักษาคุณภาพอากาศภายในอาคาร

דרגים לפי MERV מודדים את היעילות של מסנני אוויר בפיזור חלקיקים. דירוג MERV גבוה מצביע על סינון טוב יותר, כאשר מסננים בדרוג MERV 13-16 פותרים 85-95% מהחלקיקים בגודל 0.3-1 מיקרון.

מסנני אוויר יש להחליף כל 90 ימים בסביבות מסחריות סטנדרטיות, או כל 45-60 ימים בסביבות עם ריכוז גבוה של חלקיקים או פעילות רבה, כדי לשמור על ביצועים אופטימליים.

חדשות חמות

חדשות חמות2025-01-17

2025-01-13

2025-01-08

2024-12-27

2024-12-23

2024-12-16